IN LINE INSPECTION

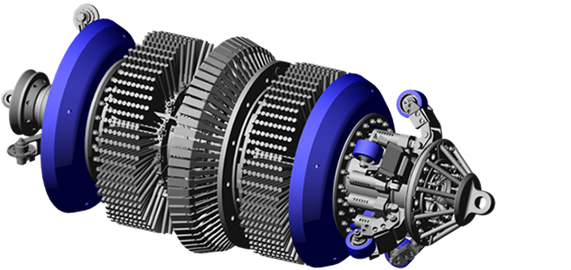

Tool designed to measure the internal cross-section and bending radius of the pipelines of different diameters.

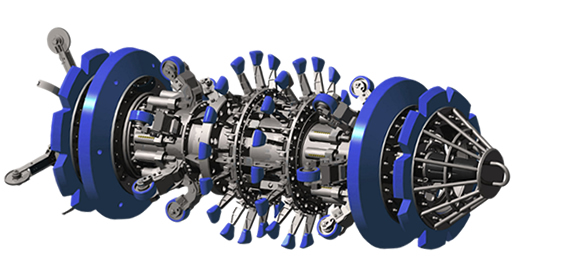

Tools designed for non-destructive testing (thickness measurement) of pipelines by ultrasonic scanning of the pipe material during the tool travel in the product flow.

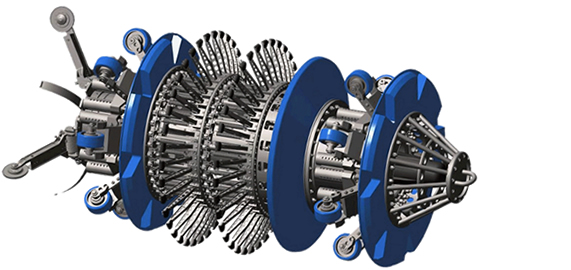

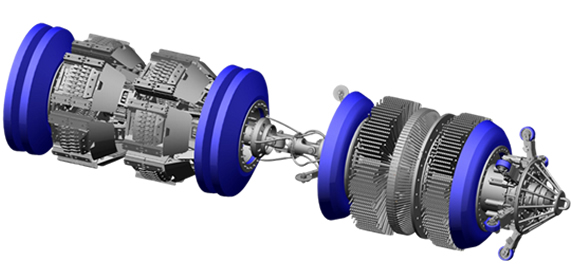

Tools designed to determine magnetic flux leakage with longitudinal magnetization of the pipeline material and transverse welds during the tool travel in the product flow.

The use of both longitudinal and transverse magnetization allows to detect various types of defects with better accuracy and efficiency, including illegal tapping and weld defects.

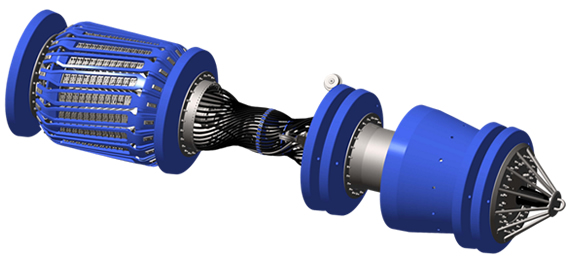

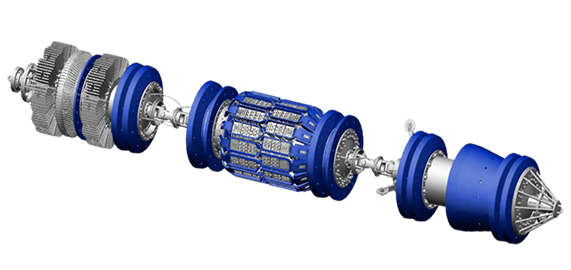

Allows to carry out both magnetic (MFL) and ultrasonic (WM и CD) inspection of pipeline for metal loss and crack in longitudinal and transverse orientation in one run. This effectively combines advantages of both methods.

© 2022 GazTech